Ar-Ge

Bezz ürün geliştirme ekibi, organizasyon içinde üretim ve pazarlama ile sürekli ilişki içinde çalışır. Bu ekip, dünyanın her yerinden farklı tasarımcılardan oluşmaktadır. Tema ve konuların belirlenmesinde mekan trendlerini takip eder. Tasarımlar, konu ile ilgili sanat yönetmenleri tarafından yönlendirilir ve izlenir. Trendler ve pazar verileri göz önüne alınarak, hikayeler tasarlanır. Koleksiyonu dışında, mekan ve mobilya tasarımcıları için onların isteği ve arzusuna göre özel ve projelerine uygun ürün tasarlar, geliştirir ve üretir. Yani, yaratıcılar için yaratır.

Farklı tarzı ile Bezz, büyük/küçük, düz/dokulu, parlak/mat gibi zıtlıkları içeren ürün seçenekleri ile tasarımcılara geniş kullanım olanağı sunar. Bezz koleksiyon tasarımlarında iplik tasarımına öncelikli yer verir. Tasarım ve üretimde tüm yeni teknikleri takip eder ve kullanır. Kendisi yeni teknikler geliştirir ve dener, farklı materyallerin kullanılmasına öncülük eder.

Bir diğer ekip ile diğer markaların koleksiyonları için ürün tasarlar veya tasarımlarını teknik olarak geliştirerek, sadece o firmalar için üretir. Bezz ürünlerinin tasarımlarını tekstildeki tüm teknikleri kullanarak yapar. Satış kapasitesinde üretim yapmaktadır. Kendine ait üretim bandında olmayan ürün çeşitlerinin üretimini, partner firmaları ile yapar. Kendi üretim kapsamı dışındaki ürünlerin üretimini, Bezz standart ve koşulları sağlayacak partner firmalarında bizzat kendi üretim sorumlularının kontrolü ve gözetimi altında gerçekleştirmektedir. Üretimde, ham iplik girişinden başlayarak ürünün teslimine dek geçen tüm süreçlerde, gelişmiş kalite kontrol ve takip edilebilirlik sistemi kullanılmaktadır.

Ürün geliştirme ekibimiz yetenekli desenciler, çizimciler ve tasarımcılardan oluşmaktadır. Bezz Studio, dijitalize bir tasarım ofisine, tam teşekküllü bir laboratuvara ve ayrıca ürünlerini 3 boyutlu görselleştirme için kullanılabilir dokular haline getiren bump mapping teknolojisine sahiptir. Mimarlar, iç mimarlar ve tasarımcılar ile işbirliği yaptığı projelerde görselleştirme için seçilen kumaşları render dokusu (texture) olarak sağlayabilmektedir.

Bezz Tech

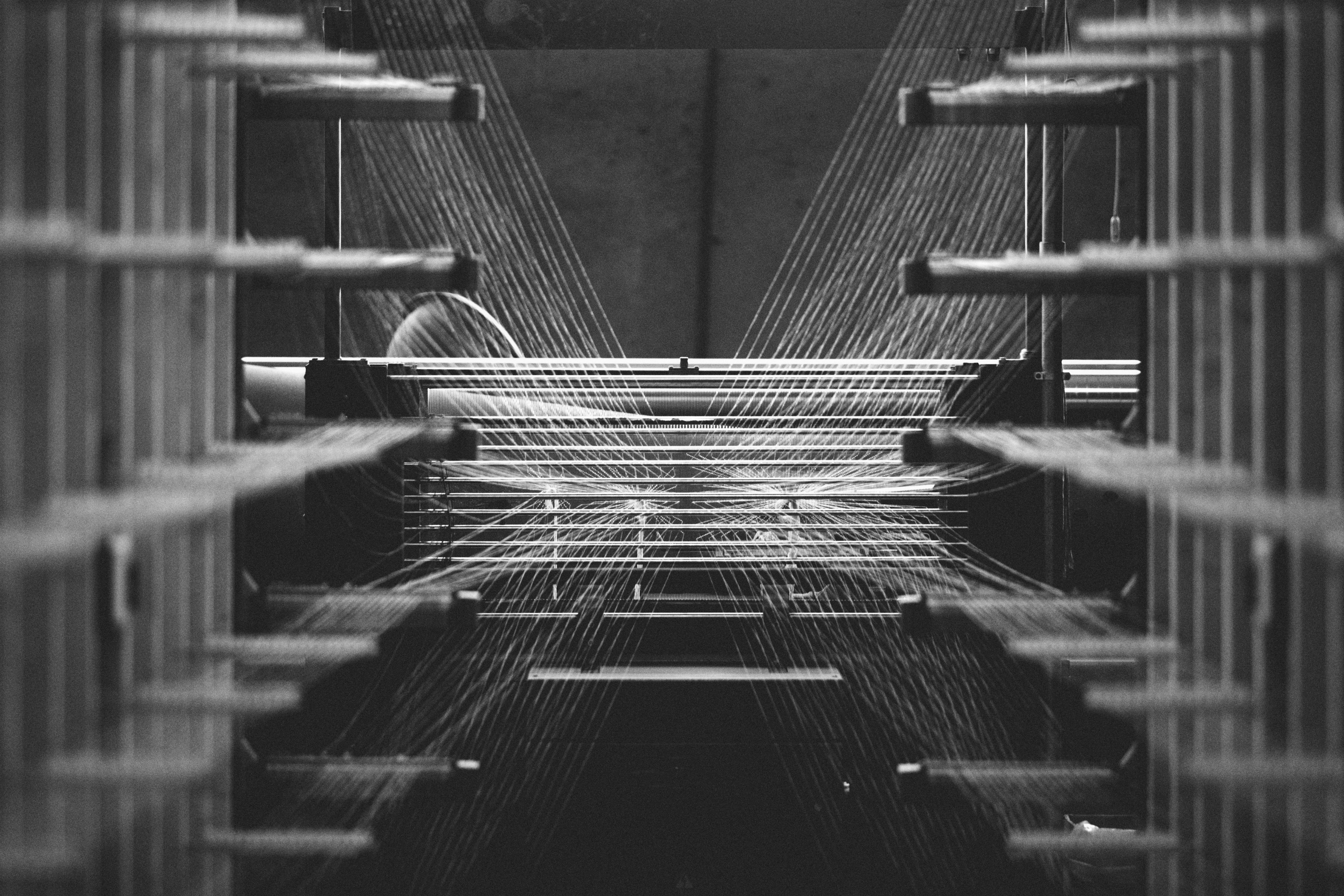

Bezz, son teknolojiye sahip bir jakarlı dokuma kurulum ve hazırlık departmanına sahiptir. Kumaşlar 140 cm veya 280 cm genişlikte temin edilebilmektedir. Bezz kumaşları ve üretimlerinde BS/EN and ISO standartları kullanılmaktadır. Üretim kendi bünyesindeki kalite kontrol laboratuvarında test edilerek kontrol edilir. Farklı standartlar istendiğinde bağımsız uluslararası denetim yapan laboratuvarlar ile çalışılır.

Apre, finishing ile sıvama (back coating) ve fularlı yanmazlık gibi alev almazlık uygulamaları; ayrıca yağ, kir ve su iticilik, antibakteriyel ve koku giderici özellikler için özel kimyasallar ile apre uygulamaları yapılmaktadır. Bezz ürünlerinde, üst düzeyde teknolojiye sahip firmalara ait dünya sağlık standardına uygun, çevre dostu boya ve kimyasallar kullanılmaktadır. Bezz kumaşları uluslararası kalite standardında üretilir ve kontrol edilir. Kalite garantisine sahiptir. Kumaşlar kullanım yerine göre gereken tüm teknik özellikleri içerir ve bu özellikler test edilerek uygulamada karşılaşılabilecek zorluklar en aza indirilir.

Bezz çok kapsamlı renk bilgisi ve çeşidine sahiptir. Koleksiyon renkleri uzun araştırmalar ve çalışmalar sonucu belirlenir ve geniş renk yelpazesi kullanır. Tüm ipliklerin kullanım öncesinde üretime ve standarda uygunluğu test edilir, lot numaraları ile renk izlenebilirliğe sahiptir. Top boya ürünlerde çalışması yapılmış 52 hazır renk mevcuttur. İplik boyalarda renk boyama için minimum miktarlarda sipariş ile istenilen renkte üretim yapılır. Müşteriye özel renk ve ürün çalışmaları yapılmaktadır. Ürün özelliğine bağlı 3 ila 5 yıl süre ile üründe devamlılık ve temin garantisi verir.